Animal feed represents the largest financial input in livestock production. It is essential to ensure that the nutritional investment is protected. Recent research conducted by Selko reveals that interventions to support the safety, stability, and shelf life of feed can support safe feed and the margins of feed and livestock producers.

Agata Kozuchowicz

Global Product Manager Fylax & Fysal

Selko Feed Additives

Responsible feed production demands a thoughtful approach not only to the inputs that go into the feed, but to addressing the threats that generate waste. Between field to fork, one-third of food produced is wasted annually, translating to $1 trillion USD. Loss occurs at multiple points across the food chain, so responsible collaboration is essential across all phases of production – including feed ingredient sourcing, processing, and storage.

Animal feed represents the largest financial input in livestock production. It is essential to ensure that the nutritional investment is protected. Recent research conducted by Selko reveals that interventions to support the safety, stability, and shelf life of feed can support safe feed and the margins of feed and livestock producers.

![]() CONSIDERING THE COST OF LOST NUTRIENTS

CONSIDERING THE COST OF LOST NUTRIENTS

Spoilage can lead to significant losses for producers. Microbes such as yeast and moulds can consume valuable nutrients in feed and produce harmful substances like mycotoxins. Therefore, adequate safeguards are necessary to prevent moulds, yeasts, and other microorganisms from proliferating and degrading nutritional value. For example, spoilage due to lost nutrients has been estimated to result in losses that range from 5% to situations where a feed’s nutritional value is completely diminished.

Beyond the loss of micronutrients like thiamine and lysine which are essential for animal performance, yeasts and moulds adversely affect the economic value of ingredients, harming the producer’s investment.

![]() Validated solutions, including blends of buffered organic acids, can help safeguard against microbial threats from raw ingredients through processing and storage. Organic acids protect against harmful bacteria and fungi by delivering a preservative benefit. But effective use of organic acids requires an understanding of their modes of action and how their combinations contribute to a feed safety solution. Distinct organic acids exert different properties that deliver variable effects against species of moulds. Additionally, the metabolic and absorption properties of various acids differ. Given that the properties exerted by individual organic acids differ and that the strengths of acidity per the pKa vary, a single organic acid cannot deliver the comprehensive approach required. Instead, a blend combining the properties of different acids is required to deliver a broad-spectrum effect against the various moulds and yeasts common in feed ingredients and finished feed.

Validated solutions, including blends of buffered organic acids, can help safeguard against microbial threats from raw ingredients through processing and storage. Organic acids protect against harmful bacteria and fungi by delivering a preservative benefit. But effective use of organic acids requires an understanding of their modes of action and how their combinations contribute to a feed safety solution. Distinct organic acids exert different properties that deliver variable effects against species of moulds. Additionally, the metabolic and absorption properties of various acids differ. Given that the properties exerted by individual organic acids differ and that the strengths of acidity per the pKa vary, a single organic acid cannot deliver the comprehensive approach required. Instead, a blend combining the properties of different acids is required to deliver a broad-spectrum effect against the various moulds and yeasts common in feed ingredients and finished feed.

ASSURING SAFETY AT THE MILL

The feed mill plays a big role in supporting feed safety, as ingredients undergo extreme thermal processes during feed production. While thermal conditioning and the application of steam can reduce contaminants in feed mass, these steps are not a panacea. Pelleting on its own may not be sufficient for killing mould spores. Moulds present a risk across all phases of production and feed treated at the mill can become recontaminated during transport or storage.

![]() Beyond reducing the microbial load in feed and feed ingredients, different organic acids can also support the longevity of feed safety interventions post production. But again, given the various contaminants and different modes of action exerted by organic acids, no single organic acid treatment can deal with such a complex matrix of safety challenges.

Beyond reducing the microbial load in feed and feed ingredients, different organic acids can also support the longevity of feed safety interventions post production. But again, given the various contaminants and different modes of action exerted by organic acids, no single organic acid treatment can deal with such a complex matrix of safety challenges.

Decades of intensive research led Selko to develop Fylax Forte-HC, a potent blend of buffered and non-buffered organic acids enriched with phytochemicals and moisture management agents. Fylax Forte-HC is a potent solution that delivers sustained feed safety benefits.

Enriching the synergistic blend with moisture management agents ensures that the active complex penetrates deep into feed particles. As a result, more of the active solution is absorbed and retained by feed. Optimal buffering of the blend enables balanced release of the antimould complex over time, prolonging feed shelf life.

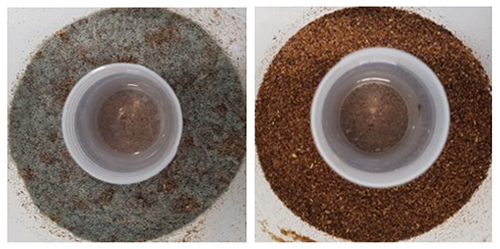

As it delivers a synergistic effect, Fylax Forte-HC is also proven effective in penetrating the mould spores and rendering them ineffective in contaminating feed. The product has demonstrated prolonged availability in feed, and this prolonged effect helps protect against recontamination of moulds in both raw ingredients and finished feed (Figure 1). Additionally, Fylax Forte-HC avoids the concerns for human and animal health posed by end-of-pipe solutions such as formaldehyde, which is prohibited in many production regions.

Dedicated dosing equipment helps ensure correct dosage, along with uniform mixing and consistent application during feed production. The result is a homogenous distribution of active ingredients through each feed batch. This gives the most effective approach to control mould and provide shelf-life longevity. Selko dosing solutions can be customized to meet specific customer needs.

FEEDING THE FUTURE RESPONSIBLY

Research demonstrates that an understanding of organic acids and their synergies can support safety as well as the longevity and quality of animal feed. Selko continues to invest in research that explores the modes of action behind science-based innovations that support feed-to-food safety.

References:

• K.E. Akande, M.M. Abubakar, T.A. Adegbola, S.E. Bogoro. (2006). “Nutritional and Health Implications of Mycotoxins in Animal Feeds: A Review.” Pakistan Journal of Nutrition, 5(5), 398–403. https://doi.org/10.3923/pjn.2006.398.403.

• C. Okoli, C. U. Nweke, C. G. Okoli, and M. N. Opara. (2006). “Assessment of the mycoflora of commercial poultry feeds sold in the humid tropical environment of Imo State, Nigeria.” International Journal of Environmental Science and Technology, 3(1), 9–14.