Antioxidation management of aqua feed raw materials is essential to prevent lipid oxidation in fish oil, soybean oil, and poultry meal, which can harm aquatic animals. Various antioxidants were tested at different dosages, showing differing efficacy in prolonging stability and reducing MDA formation. Results indicate that proper antioxidant selection can significantly improve raw material freshness, though effectiveness varies among oils and meals, encouraging further evaluation of optimal formulations.

Global Project Manager

Kemin AquaScience

Lipid oxidation refers to the chemical degradation of lipids, particularly unsaturated fatty acids, and it plays a crucial role in food spoilage, biological aging, and disease processes. There are three main forms of lipid oxidation, autoxidation, enzymatic oxidation and photooxidation. Autoxidation (also Free Radical Oxidation) is the most common form and occurs spontaneously in the presence of oxygen. It consists of three phases: initiation, where lipid radicals are formed, propagation where a chain reaction lipid peroxides are formed, and termination where radicals combine to non-radical products. The breakdown products of lipid peroxides are responsible for the rancid smell and consist of aldehydes, ketones and alcohols. Enzymatic oxidation occurs in living organisms and involves the presence of lipoxygenase, cyclooxygenase or cytochrome P450. Lipoxygenase can be present in feed ingredients of vegetable origin, such as soybean meal, and catalyze the reaction between free fatty acids and oxygen, with formation of lipid peroxides. Photooxidation involves the presence of photosensitizers, such as chlorophyll or riboflavin, that after excitation by light, can transform triplet oxygen to singlet oxygen. Singlet oxygen can react directly with fatty acids with the formation of lipid peroxides.

Substantial evidence indicates lipid oxidation detrimentally impacts aquatic animal health. Lipid levels in aquafeeds, particularly for carnivorous species, commonly reach 15-16%. They exceed 30-35% in formulations for cold-water fish like Atlantic salmon. Consequently, lipid freshness is paramount for optimal aquatic animal growth and health. Regrettably, commercially available lipid sources (animal fats, vegetable oils) have been found to be of inconsistent quality and freshness frequently. Present study investigates the efficacy of various antioxidants on fish oil, soybean oil and poultry meal.

MATERIALS AND METHODS

Three liquid antioxidant samples of product BC, product DBX, product YZD and two powder antioxidants of product ATY and product KYB were collected from two feed mills from Zhuhai city and Wuhan city, China. Two kilograms of each product were sampled from an unused 20kg package and sealed in a light proof sample bag or bottle. All the samples were then shipped to Kemin Zhuhai laboratory. Two liquid antioxidants, BaroxTM and Oxivia C200LQ, and one powder antioxidant Oxivia C200DR were from Kemin Industries. The fish oil and soybean oil samples with no antioxidant were collected from a feed mill in Zhuhai, China. Stability of control and treated oils was tested in the Oxidative Stability Instrument (OSI). In this test the oil was heated to 80°C (fish oil) or 100°C (soybean oil) and continuously flushed with air (5.5 psi). This accelerates oxidation, with the formation of volatile oxidation products. These are trapped in water in which conductivity is continuously measured. The time to reach a sharp increase in conductivity is named the induction time, the higher the induction time, the more stable the oil is. In the tests the liquid antioxidants were dosed at 500 and 2000 g/T oil.

The poultry meal with no antioxidant was collected from feed mill in Guangzhou, China. These samples were treated with Oxivia C200DR at 500g/T or Product ATY at 550g/t. Samples were mixed evenly, sealed in light proof bag, and stored in room temperature. Every seven days malondialdehyde (MDA) content in the meal was determined. MDA is a lipid oxidation reaction product, and can be measured as TBARS, according to Chinese National Standard: GB 5009.181-2016. The higher the MDA level, the more the meal is oxidized.

![]() Poultry meal was also treated for analysis in the RapidOxy test. In this test a sample is heated and put under pressure using oxygen. When the sample oxidizes, pressure will decrease. The time required to reach a 10% pressure decrease is considered as measure for oxidative stability. The longer this time, the more stable the sample. For this test Oxivia C200DR was added to the meal at 500 g/T and product KYB at 600g/t.

Poultry meal was also treated for analysis in the RapidOxy test. In this test a sample is heated and put under pressure using oxygen. When the sample oxidizes, pressure will decrease. The time required to reach a 10% pressure decrease is considered as measure for oxidative stability. The longer this time, the more stable the sample. For this test Oxivia C200DR was added to the meal at 500 g/T and product KYB at 600g/t.

RESULTS AND DISCUSSION

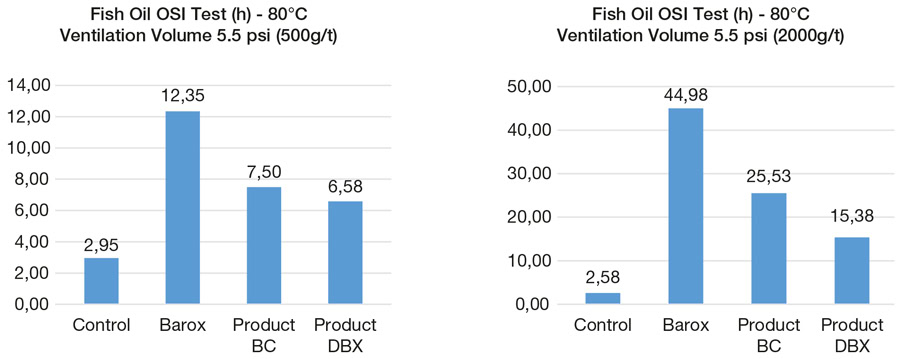

The impact of antioxidant treatment of fish oil was tested in the OSI at 80°C. In two studies three different liquid antioxidants were evaluated. As can be seen from Figure 1 and Figure 2, the induction period of trial groups (fish oil supplemented with antioxidant) was higher than that of control group. At 500g/t dosage test, the longest induction period of 12.35 hour was found in group Barox, an antioxidant from Kemin Industries, which is 64.67% and 87.69% higher than that of Product BC (7.50 hour) and Product DBX (6.58 hour), respectively. Similar results were found at 2000g/t test (Figure 2), highest data was found in Barox group, which is 76.18% and 192.46% higher than that of Product BC and Product DBX, respectively.

Figure 2. Oil stability index test of fish oil at dosage of 2000g/t at 80°C, ventilation volume 5.5 psi

It is obvious that supplements with antioxidants can prolong the induction period of fish oil and prevent oxidation. Furthermore, in present study Barox performed the best, far outperforming the other two antioxidants. Interesting results were observed at 2000g/t test in comparison with 500g/t test that the efficacy gap between Barox and two other antioxidants is enlarged once dosage is high.

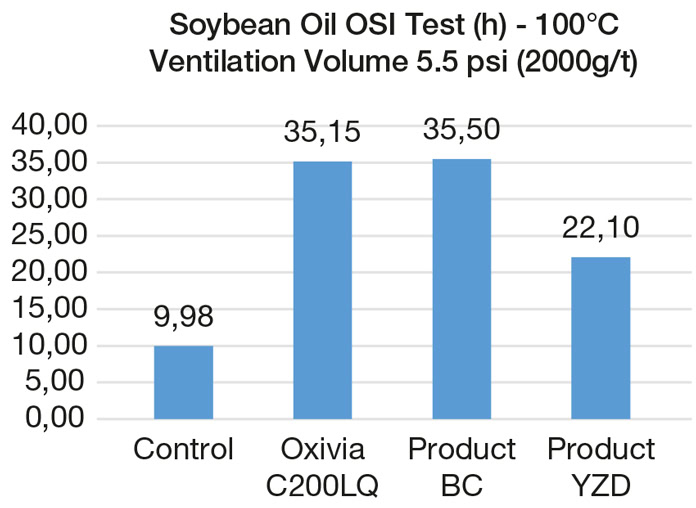

Impact of addition of antioxidants on stability of soybean oil was tested in the OSI at 100°C. For this test inclusion of antioxidants was 2000g/t. It can be seen from Figure 3 that all the antioxidant groups, Oxivia C200LQ, Product BC and Product YZD, were better than the control group. The efficacy of group Oxivia C200LQ and Product BC was basically the same and way better than Product YZD.

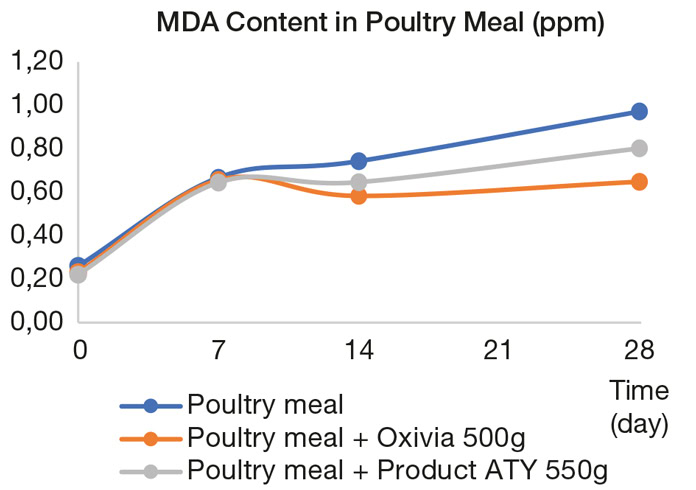

Evolution of MDA content in control and treated poultry meal at room temperature was tested at one, two and four weeks. The initial purpose of the present study was to evaluate the efficacy of antioxidants on controlling MDA formation in poultry meal, where two different dosages were introduced to determine if Oxivia C200DR (from Kemin Industries) is comparable with a 10% higher dosage of Product ATY.

Results in Figure 4 showed that from day 0 to day 28, all data of MDA content was lower than 1.0 ppm indicating non-oxidation occurred, however the overall trend of MDA content in poultry meal was increased gradually. The maximum value, 0.97 ppm, was achieved in the poultry meal control group on the 28th day, which indicated that with no antioxidant in poultry meal the oxidation is more severe and thus harmful oxidative product accumulated more. Compared with group Product ATY 550g, lower MDA content of 0.65 ppm was found in group Oxivia 500g. Therefore, according to the present study, the antioxidative efficacy of Oxivia C200DR is equal to a 10% higher dosage of Product ATY. It may be because Oxivia C200DR has better uniformity and granularity, leading to evenly mixing.

RapidOxy test of poultry meal samples were conducted at 120°C and 7par. The purpose of the study was to evaluate the efficacy of two antioxidants, where two different dosages were introduced to determine if Oxivia C200DR (from Kemin Industries) is comparable with a 20% higher dosage of Product KYB.

![]() It can be seen from Table 1 that the antioxidant groups, Oxivia C200DR and Product KBY, were better than control group. The RapidOxy result of Oxivia C200DR was 111.4 minutes, which is slightly higher than that of product KYB. Similar with poultry meal MDA test, each gram of Oxivia C200DR, with better uniformity and granularity, has more particles than that of product KYB, thereafter it enhances the even mixing and distribution inside the raw material. It may explain that the 20% lower dosage of 500g/t of Oxivia C200DR performs better than higher dosage 600g/t of product KYB.

It can be seen from Table 1 that the antioxidant groups, Oxivia C200DR and Product KBY, were better than control group. The RapidOxy result of Oxivia C200DR was 111.4 minutes, which is slightly higher than that of product KYB. Similar with poultry meal MDA test, each gram of Oxivia C200DR, with better uniformity and granularity, has more particles than that of product KYB, thereafter it enhances the even mixing and distribution inside the raw material. It may explain that the 20% lower dosage of 500g/t of Oxivia C200DR performs better than higher dosage 600g/t of product KYB.

CONCLUSION

Oxidation of raw material is very harmful to aquatic animals while antioxidants are one of the critical solutions to prevent raw material oxidation, including poultry meal, fish oil and soybean oil, etc. Various antioxidants were collected from the market and have been evaluated to determine efficacy. Results demonstrated that in total four liquid antioxidants and two powder form antioxidants performed well in present study. Among these, Barox performed best in fish oil, Oxivia C200LQ and Product BC worked well in soybean oil and Oxivia C200DR was the best in poultry meal by considering the amount of dosage.

About Richard Liu

With a Master’s degree in Feed Manufacturing Technology from the Norwegian University of Life Sciences, Norway, Richard Liu has been actively involved in aquaculture product development and management since 2015. Liu currently serves as a Global Project Manager. In his role, he works closely with feed mills to develop and optimize nutrient efficiency and feed safety solutions. His work is fundamentally aligned with the principles of sustainable aquaculture. By advancing feed efficiency and safety, it directly contributes to reducing waste and resource consumption in farming.