Smart monitoring in feed production is transforming how facilities manage safety, efficiency, and sustainability. As manual inspections give way to real-time digital visibility, innovative systems like SiloSpi reduce waste, improve worker safety, and enhance environmental performance. With growing demands and stricter goals, smart technologies are becoming essential tools in the evolution of modern feed mills.

CEO and Co-Founder

LvLogics

Like all others worldwide, the animal nutrition industry faces two fundamental challenges, how to meet growing global demand without compromising worker safety, and how to achieve that without damaging the planet. In wrestling with this challenge, a technological revolution is quietly transforming how feed storage facilities manage their most fundamental resource: inventory.

THE NUMBERS TELL THE STORY

Animal agriculture, which heavily depends on feed crops, is responsible for about 14.5% of all human-caused greenhouse gas emissions globally.1 In the United States, livestock farms generate approximately 70% of the nation’s ammonia emissions, which contribute to air pollution and climate change, particularly through methane production.2

The American Feed Industry Association (AFIA) and the U.S. dairy industry have set goals to reduce the carbon footprint of animal agriculture, aiming for carbon neutrality, optimized water use, and improved nutrient management by 2050.

When it comes to worker safety, falls from grain or raw material bins are the second most common cause of injury or death worldwide after entrapments. However, as there are no comprehensive or mandatory incident or injury reporting systems for most of agriculture, many incidents are thought to go unreported. From 2005 to 2015, the U.S. averaged 35 incidents annually, with 60%–70% fatalities, though falls were not separately categorized.3

Even with improved safety protocols in place, manual inspections remain inherently dangerous.

Then there’s waste. Currently, over $2 billion is wasted globally each year due to inefficient animal feed delivery.

FROM DANGER ZONES TO DIGITAL VISIBILITY: THE EVOLUTION OF FEED STORAGE MONITORING

Smart monitoring systems are changing the game, replacing dangerous manual practices with data-driven solutions that enhance safety while driving measurable improvements in environmental impact.

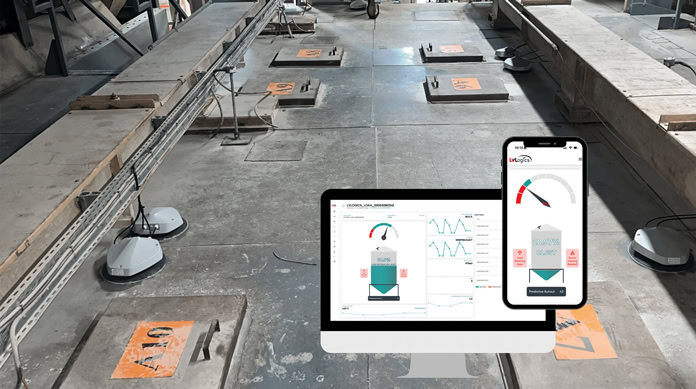

These modern solutions allow operators to view feed inventory information on phones, tablets, or computers, automatically measuring bin levels and projecting consumption without the need to climb the bin. Using various sensor technologies – from radar and ultrasonic sensors to cable-based measurement devices and lasers – they provide continuous, real-time visibility into storage levels.

Our technology, SiloSpi, allows mill operators to access their data 24/7, collecting precise information on levels inside a silo and transmitting it wirelessly to a secure cloud host. Each individual sensor uses an IoT radio protocol that has a two-mile radius, making connectivity to the cloud via a base station very straightforward. One of SiloSpi’s standout features is its air-driven self-cleaning technology, which activates only when the sensor detects dust build-up. This innovative self-cleaning capability ensures consistent performance over time.

ENVIRONMENTAL SAVINGS

By providing mill operators with real-time data on feed levels in their customers’ bins, smart systems like SiloSpi make possible a more sustainable and efficient delivery process.

Data-driven, proactive processes help reduce the number of emergency deliveries and partial loads to farms. Demurrage costs and inefficiencies as trucks wait to be dispatched add to costs of transportation and can be minimized with the right data. Reducing the number of trucks on the road—or idling—leads to significant financial savings. It also enhances sustainability performance, representing a win for the mill and the planet.

The environmental benefits extend beyond energy savings to include significant waste reduction. When farms order the right amount of feed, they reduce the amount of feed left over when animals are sent for processing, reducing wasted feed, vacuuming, and disposal charges.

Automated systems also result in reductions in energy usage while contributing to enhanced sustainability practices. These systems optimize energy consumption without compromising operational efficiency, resulting in improved product quality and reduced overall plant running hours.

ADDITIONAL BENEFITS

The benefits of this technological revolution extend beyond eliminating dangerous manual inspections and reducing environmental impact.

Automated alerts via text or email allow for proactive actions, enabling mills to react to inventory changes without putting personnel at risk. Manual inspections also lead to production delays, emergency deliveries, and inefficient resource allocation. Smart monitoring systems provide unprecedented operational transparency that enables proactive decision-making across the entire production chain.

Of course, more efficient operations impact a business’s bottom line too.

Industry data shows that every bin monitored by smart systems delivers an annual ROI of 4-5x. This return comes from reduced labor costs, eliminated emergency deliveries, optimized inventory carrying costs, and improved production efficiency. We believe SiloSpi, with its unique approcah to level sensing can do even better, delivering a 7x return on investment over a three-year period.

SMART MILLS WILL ONLY GET SMARTER

The rapid evolution of tech represents a real opportunity for mill owners to further streamline their operations.

Manufacturing Execution Systems (MES) are the next step in feed mill automation, turning gigabytes of data into useful information by connecting transactional, production, and equipment data in the same database. This integration enables comprehensive reporting from a single source while eliminating manual data entry and reducing errors.

The development of Artificial Intelligence (AI) and Machine Learning models will alter how the industry approaches mill design and operations. AI systems can analyze historical data patterns to optimize formulations, predict equipment maintenance needs, and identify process improvements.

The connected ecosystem extends beyond the mill walls to encompass the entire feed supply chain. Blockchain technology and other traceability solutions track ingredient sourcing, production processes, and product distribution, creating end-to-end visibility that supports both regulatory compliance and quality assurance.

Smart factory implementations have shown projected improvements in manufacturing throughput between 10 and 15 percent. In feed mill applications, this translates to significant productivity gains while reducing labor requirements and operational costs.

Select systems enable troubleshooting problems remotely, reducing downtime and expense for both equipment manufacturers and their customers. In feed mill applications, this capability means that what previously required hours of investigation to identify equipment problems can now be accomplished in seconds.

Feed mill automation also simplifies regulatory compliance for rules like the Food Safety Modernization Act (FSMA). Smart monitoring systems provide the detailed records and traceability required for regulatory compliance while reducing the administrative burden on mill operators.

The cumulative impact of these improvements creates a compelling business case for smart monitoring adoption. Feed mill automation drives ROI by making it easier to run multiple processes simultaneously while reducing error between each process. This multiplier effect means that benefits compound as systems become more integrated and sophisticated.

THE FUTURE

The path forward involves continued integration of complementary technologies. Feed mill owners need clear data to measure what is happening in their mills and control operations using data collection to monitor health, position, and performance. This intelligence enables predictive maintenance and process optimization that drive continuous improvement.

As the industry moves toward more connected and intelligent operations, the role of smart monitoring systems like SiloSpi will continue to expand. These systems serve as the foundation for broader digital transformation initiatives that promise to make feed production safer, more efficient, and more environmentally sustainable.

The evidence is clear: Smart monitoring systems represent more than just a technological upgrade – they are a fundamental enabler of the modern, connected feed mill. As the industry continues to evolve, facilities that embrace these technologies will be better positioned to meet the challenges of tomorrow while delivering superior safety, efficiency, and environmental performance today.

References

1Factory Farming: A Recipe for Disaster for Animals & Our Planet

2The Animal Feed Industry’s Impact on the Planet

3https://ilt.safetynow.com/grain-bin-safety-stats-and-facts

About Barry Finnegan

The Co-founder of Lvlogics, Barry Finnegan brings a unique blend of hands-on farming insight and technical expertise to the world of agricultural innovation. Growing up in a dairy farming family, Finnegan witnessed firsthand the challenges farmers and animals face when feed supplies run low unexpectedly. This deep understanding of on-farm pressures—combined with his MSc in Electronic Engineering and years of experience in remote oil monitoring—inspired him to pioneer a groundbreaking solids monitoring solution.

He recognized that laser technology, known for its reliability, accuracy, and affordability in level sensing, could revolutionize feed monitoring—if one critical hurdle could be overcome: dust interference in silos. Determined to solve this challenge, he engineered an innovative solution, paving the way for SiloSpi, a low-cost, reliable monitoring system designed to give millers and farmers real-time visibility and peace of mind.

At the heart of Finnegan’s work is a passion for creating meaningful, user-driven technology.