Moisture management has become a strategic pillar of feed mill performance. Better moisture control not only protects feed quality and safety, but also boosts operational efficiency, reduces costs and enhances profitability. Feed mills should be auditing their current water activity control and considering moisture management as a strategic focus to improve output and profitability.

Mill Optimization Product Manager

Perstorp Group

Feed mills face constant challenges balancing variables such as raw material availability, pellet quality and production efficiency. Moisture management is an often-overlooked area of feed production. It may seem simple, but it’s a highly sophisticated discipline at the heart of feed manufacturing efficiency. Every percentage of moisture lost during pelleting translates into reduced volume, compromised durability, and higher energy costs. Moisture management is an important factor to be considered by feed mills, especially because of the impact it has on feed cost and mill performance.

Moisture management may seem simple but is in fact a highly sophisticated discipline with efficiency at its core. New technologies have furthered our understanding of the importance of water activity in feed, giving rise to patented solutions like ProSid™ Pellet Pro.

WHY MOISTURE MATTERS

Water is a critical part of the nutritional specification of feed. Pelleting and heating cause water losses of around 3% through evaporation. When moisture levels drift below intended targets, mills lose production volume. Additionally, the pellets are often compromised in terms of quality, often with reduced uniformity, poor consistency and compromised durability. Conversely, poorly managed added water increases water activity, heightening the risk of microbial growth.

Moisture influences many areas of feed

production including:

1. Feed safety – the contamination risk grows significantly when water activity is high. Most bacterial pathogens cannot proliferate below a water activity of 0.9, and most molds are inhibited below 0.65.

2. Milling efficiency – moisture evaporation accounts for a 1-3% loss of final feed tonnage, equivalent to 40 million tons of saleable feed worldwide. These losses are compounded during dry seasons or in high friction milling environments. More energy is consumed and throughput is lower.

3. Pellet quality – insufficient moisture in the mash reduces steam uptake which weakens pellet adhesion, leading to poor starch gelatinization and reduced hardness.

4. Animal performance – it is a misconception that drier feed improves feed conversion. Optimal moisture levels in the feed mean starch gelatinization is improved and feed digestibility increases, therefore supporting improved animal performance.

What is water activity?

Moisture percentage tells us how much water is present in the feed. Water activity (aW) is a measure of the water available for microbial growth and chemical reactions ranging from 0 (completely dry) to 1.0 (pure water). An aW over 0.65 is conducive to mold growth. Factors such as temperature, humidity, storage conditions and internal water migration all influence water activity. The central goal of a moisture management program is to reduce the aW.

MOISTURE MANAGEMENT TECHNOLOGIES

Traditional moisture management products relied on surfactants and propionic acid which lack longevity, stability and consistency in commercial milling conditions. Esters of fatty acids are well known emulsifiers and surfactants.

ProSid™ Pellet Pro represents a breakthrough in moisture management solutions and contains:

• Glycerol esters of propionic acid which:

– allow for more penetration of moisture in the feed materials,

– help to draw water into the feed pellets as bound moisture,

– support mold inhibition programs, improving the shelf life of the final feed,

– have a prolonged efficacy,

– are stable, less-corrosive with no dangerous goods restrictions on transport or storage.

• Surfactants which substantially lower the water surface tension for improved moisture distribution.

• Glycerol which acts as a humectant, capable of holding many times its own weight in water.

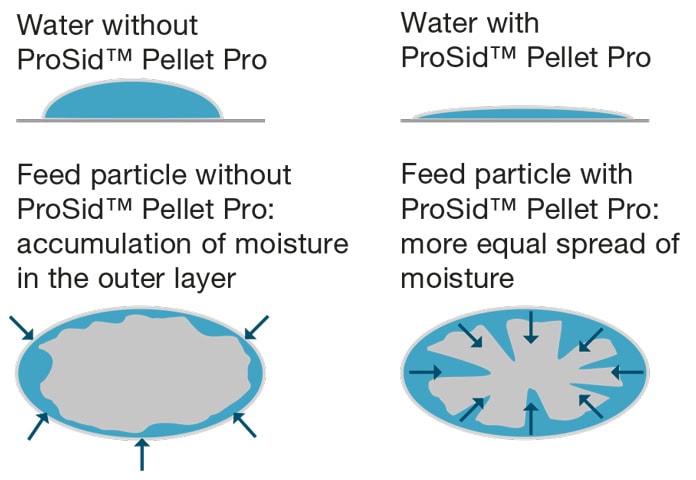

The combination of activities in ProSid™ Pellet Pro (Figure 1):

• Enhances moisture absorption into feed particles, giving feed producers the ability to replace moisture that evaporates during pelleting, increasing volumes and throughput.

• Reduces free water and lowers water activity (aW) which supports microbial control.

• Improves starch gelatinization which reduces moisture migration and caking for improved pellet quality.

• Reduces volatility leading to the persistence of the product and its functions.

ProSid™ PELLET PRO IN PRACTICE

ProSid™ Pellet Pro has been tested in many commercial trials in various feed mills and extruder plants, with consistent results throughout (Figure 2).

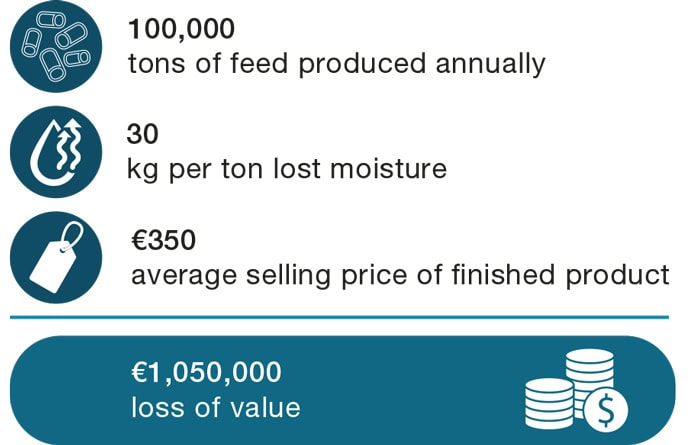

In practical terms, ProSid™ Pellet Pro mitigates moisture losses of up to 3%, therefore recovering up to 3,000 tons of feed in one year for a feed mill that produces 100,000 tons annually.

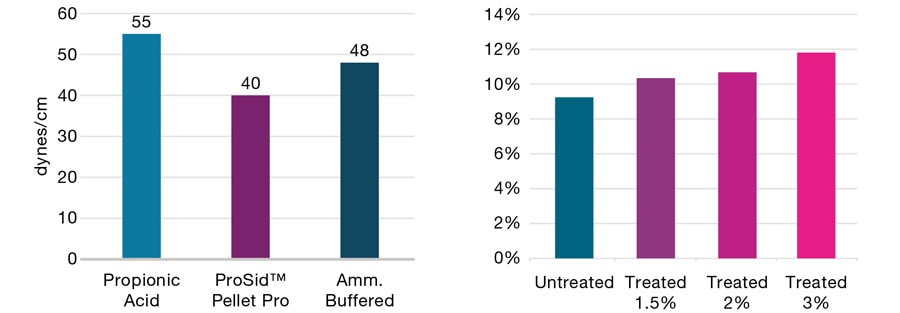

ProSid™ Pellet Pro is more effective at reducing water surface tension than propionic acid and an ammonium buffered moisture management solution (Figure 3).

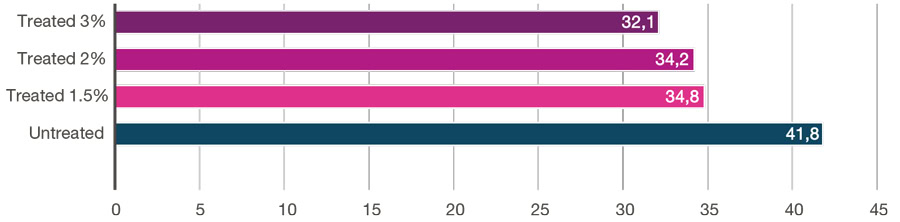

ProSid™ Pellet Pro improves moisture retention compared to untreated feed (Figure 4).

Figure 4. Moisture retention trial data. ProSid™ Pellet Pro increased water retention by up to 28% more compared to the untreated feed

ENERGY SAVINGS

ProSid™ Pellet Pro helps optimize milling operations by improving throughput by up to 18%. In one trial, the throughput improvements of feed treated with ProSid™ Pellet Pro compared to the untreated feed led to 23% less energy (kWh) being used (Figure 5). This reduction in energy consumption due to the lubricating effect of feed containing optimal levels of moisture and the reduced drier requirements equate to savings of up to €1.10 per ton.

In summary, there are many benefits of using ProSid™ Pellet Pro including:

• Moisture losses of up to 3% are mitigated,

• Water is more evenly distributed in the feed which preserves high pellet quality and uniformity,

• Cost savings due to lower energy requirements,

• Improved pellet uniformity, consistency and durability,

• Higher throughput – more feed produced in the same amount of time,

• Improved pellet quality has been shown to improve feed intake which supports optimal animal performance.

MOISTURE MANAGEMENT IS NO LONGER OPTIONAL

As global demand for high-quality and safe feed grows, moisture management has become a strategic pillar of feed mill performance. Better moisture control not only protects feed quality and safety, but also boosts operational efficiency, reduces costs and enhances profitability. Feed mills should be auditing their current water activity control and considering moisture management as a strategic focus to improve output and profitability.

About Antony Wildon

Graduating from the Faculty of Animal Science at The University of Pretoria, Antony Wildon entered a career as a monogastric nutritionist in various roles from the nineties with a heavy focus on companion animal product development and aquaculture management and nutrition both in South Africa, neighboring countries and the rest of EMEA. The last decade has seen a role change to the feed additives arena where a solid background in animal health and nutrition support his offering to the market. Experience with feed mills across EMEA over the last 12 years has also strengthened his knowledge and approach to a practical way of doing business in an ever-demanding animal production sector. Wildon has been with Perstorp Animal Nutrition over 6 years and based in England, is currently Mill Optimization Product Manager whilst also managing a diverse portfolio of sales responsibilities.