Liquid antioxidant application ensures that pet food products remain safe for animals throughout their intended shelf life. Effective management of fat oxidation is increasingly important as sustainability initiatives prompt manufacturers to reduce packaging layers. These modifications may result in greater oxygen migration, potentially accelerating fat oxidation processes. Antioxidants must be incorporated with precision at optimal dosages to ensure product shelf life and comply with the European Union’s regulations on maximum permitted levels of antioxidant molecules.

Principal Technical Service Manager

Kemin Nutrisurance Europe

Fat oxidation in pet food raw materials and finished products is a critical concern, as it can negatively impact both nutritional quality and palatability, ultimately affecting pet health. To control these issues, antioxidant molecules are systematically incorporated throughout the pet food production chain, as illustrated in Figure 1.

Oxidation can begin as early as the raw material management stages and continue throughout all pet food processing and storage steps, up to the moment the product is fed to the animal. To address this, antioxidants—available in both liquid and dry forms—are applied at nine key points throughout the production process, from raw material handling to finished product processing. While both types play essential roles in maintaining product quality, liquid antioxidants are selected for approximately 80% of applications due to their versatility and strong performance across diverse production scenarios.

ADVANTAGES OF LIQUID ANTIOXIDANT FORMULATIONS

Liquid antioxidants offer significant benefits in terms of homogenization and distribution:

• Fresh meat and animal by-products (ABP): Liquid antioxidants form stable emulsions, ensuring uniform penetration.

• Processed Animal Proteins (PAP): Effective dispersion across dry matrices via advanced spray technologies.

• Liquid/liquid systems: When applied to animal fats, static mixing technologies enable optimal blending and antioxidant molecular interaction.

Spray application remains the predominant method for dry matrices, where air-assisted spray systems achieve fine particle coverage.

Liquid Antioxidant Formulation Complexity

Liquid antioxidant solutions are engineered for:

• Synergistic molecular activity to enhance oxidative stability.

• Metal-binding properties to neutralize pro-oxidant catalysts.

• Enhancing molecule efficacy through tailored carrier systems.

• Viscosity optimization to ensure compatibility with diverse application technologies.

These formulations represent a balance of antioxidant functional performance, chemical stability, and process adaptability, making them indispensable for modern pet food manufacturing. These liquid solutions have specific and different viscosity values, based on their formulation.

CHALLENGES: UNDERSTANDING VISCOSITY AND ITS ROLE

Viscosity, as defined by Newton’s law, is the resistance of a fluid to flow—caused by molecular interactions and friction. It is measured in units such as Pascal-second (Pa·s), or Centipoise (cP).

Here’s the key principle:

• Higher viscosity = slower flow

• Lower viscosity = faster flow

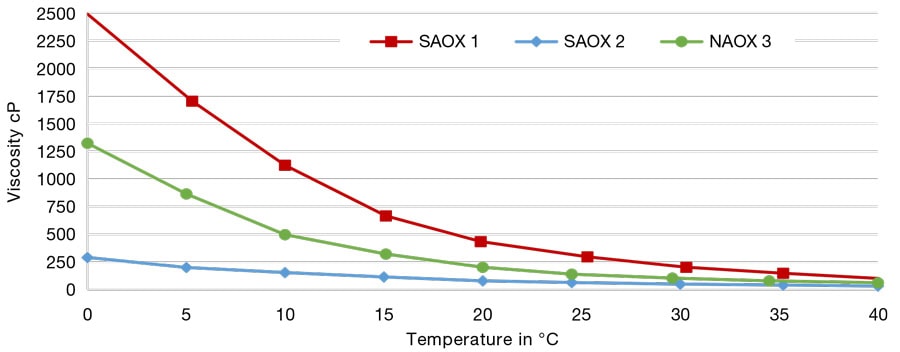

And temperature plays a major role: as temperature increases, viscosity decreases. This means that the same antioxidant solution behaves very differently at 10°C compared to 25°C as described in Figure 2.

Our studies show that viscosity varies significantly among antioxidant solutions, depending on active molecule concentration and carrier systems. For example:

• SAOX 1 (BHA/BHT on vegetable carrier)

• SAOX 2 (BHA/Propyl Gallate/Citric Acid on specific carrier)

• NAOX 3 (Mixed Tocopherols/Rosemary extract on vegetable carrier)

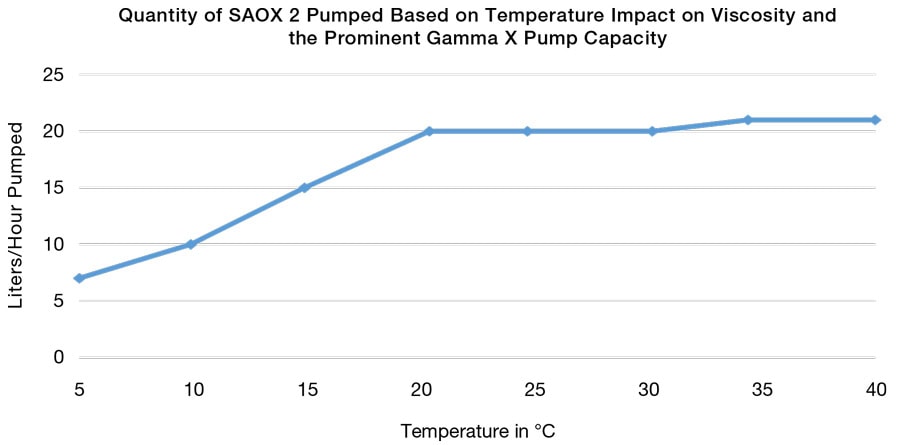

Each formulation has its own viscosity profile and therefore requires a dedicated application line tailored to that specific antioxidant (including suction line, pump, piping and nozzle). It’s crucial to maintain always the same temperature as the liquid antioxidant and keep the pump calibrated with the temperature of use. If not, we can observe significant variations in the amount of antioxidants applied, as shown in Figure 3.

Critical temperature ranges from 5 to 20ºC impacting the dosage, which corresponds to the exponential decrease of SAOX 3 mentioned in Figure 2. If we apply SAOX 3 at 10ºC instead of 20ºC, pumps will deliver less than 10L per hour which is half of the quantity expected in this example. Conversely, highest temperature will deliver more antioxidants than targeted.

These temperature variations reflect EU seasonality and also the lack of temperature control. Especially during winter. Rendering companies and pet food manufacturers are often highlighting some fat oxidation increases trend with higher Peroxides Values and Hexanal recoveries increase. But in parallel, antioxidant molecules recoveries are decreasing a lot related to liquid antioxidant application challenges.

Key challenges include insufficient or decreased use of antioxidant solutions. A direct result is reduced product shelf life, potentially leading to end product recalls.

During the summer period we notice occasionally higher antioxidant recoveries levels. In this context, the primary concerns may involve surpassing the rate of antioxidant molecule recovery in final pet food production, as well as potential increases in the associated costs of antioxidant usage.

TAKE AWAY

Between 10ºC and 25ºC, viscosity changes dramatically, impacting pump performance.

• Cold conditions (winter): Higher viscosity → pumps deliver less antioxidant → underdosing

• Hot conditions (summer): Lower viscosity → pumps deliver more antioxidant → overdosing

Consequences include:

• Winter: Increased fat oxidation, higher peroxide values, reduced shelf life, potential product recalls

• Summer: Excess antioxidant levels, regulatory compliance risks, and higher treatment costs.

HOW TO SECURE THE RIGHT ANTIOXIDANT APPLICATION

Main rules to respect are good practices in term of:

1. Application and pump calibration

2. Weather anticipation

3. Liquid antioxidant temperature control

Liquid application practices

Before initial use, pump calibration should be performed at the same temperature as that of the intended liquid application. It is essential to record the liquid temperature and document it in the calibration report. Whenever there is a change in temperature, recalibrate the pump accordingly. Regularly monitor antioxidant consumption as per established guidelines.

Always apply liquid antioxidants at the originally specified temperature, typically within the range of 20ºC to 30ºC.

Weather condition changes

It is essential to maintain consistent control and monitoring of the liquid antioxidant temperature both prior to and during application. Temperature sensors are typically used in the antioxidant Intermediate Bulk Container (IBC), drum, or bidon, while certain flowmeters can also relay temperature data. All collected information can be managed via a Programmable Logic Controller (PLC) or directly through connected technologies such as Kemin sciORIANTM.3 This system enables real-time collection of data including temperature, flow rate, quantity administered, bulk and stock levels, and pump status. Operators actively oversee temperature and application in real time. Should any issues arise, such as temperature reduction or pump failure, alert notifications are sent by email. All data is recorded to ensure full traceability.

Prior to installing a new IBC, drum, or Jerrycan, it is important to verify the temperature. As a standard procedure, allow the container to acclimate for several days near the existing antioxidant liquid. If required, gently warm the container to reach the desired temperature.

Temperature control

As mentioned above, it’s crucial to maintain the right liquid antioxidant temperature in the IBC/Drum/Jerrycan, in the suction line and in the pump, but also up to the nozzles.

For antioxidants’ temperature management, specific heated containers with temperature control or heating jackets with thermostat are used. For the last one, some internal temperature sensors are recommended to avoid overheating, especially when temperatures are increasing in spring.

Sometimes nozzles application points are located at more than 15m of the pumps. In this case, pipes can go outside the plants or in cold areas. We suggest equipping along pipes with some heating tracer for maintaining a constant temperature. Higher temperature improves the antioxidant dispersion, mixing and efficacy.

CONCLUSIONS

The application of liquid antioxidants ensures that pet food products remain safe for animals throughout their intended shelf life. Effective management of fat oxidation is increasingly important as sustainability initiatives prompt manufacturers to reduce packaging layers. These modifications may result in greater oxygen migration, potentially accelerating fat oxidation processes.

Antioxidants must be incorporated with precision at optimal dosages to ensure product shelf life and comply with the European Union’s regulations on maximum permitted levels of antioxidant molecules.

As the climate continues to evolve and overall temperatures rise, we are experiencing increasingly erratic and unpredictable temperature fluctuations throughout the year. These variations can affect the dosing of liquid antioxidants. The implementation of new connected technology, equipped with comprehensive sensors and alarm systems, will assist us by anticipating changes in liquid temperature and maintaining consistent temperatures over time. While it is important to select efficient antioxidant solutions, their precise and proper application remains critical to achieving optimal results.

References

1Kemin Nutrisurance COMM-24-26907

2Estimation done based on Prominent Gamma X DS and internal Viscosity data

3SciORIANTM Kemin connected Technology for monitoring pump, stock and many sensors

4Internal Kemin viscosity data

About Frank Clement

Based in France, Frank Clement is a Principal Technical Service Manager (TSM) and the Kemin Application Solutions (KAS) Manager of Kemin Nutrisurance Europe. He coordinates EU antioxidant, preservatives, and palatability TSM team projects. During the past 11 years, he’s spent a lot of time in slaughterhouses and rendering plants to evaluate the best strategy to preserve the freshness of raw materials and guarantee safe end pet food products. He has been at Kemin for 16 years, mainly focusing on antioxidation subject and especially on EU Natural Antioxidant transition. As a biochemist, he’s spent more than 34 years at the pet food industry and especially on the analytical part at the beginning of his career.