Botanical feed ingredients are functional plant-based compounds that can support animal welfare, performance, and sustainable production. To fully realize these benefits, the stability of their active ingredients during processing and storage – as well as their targeted application – is crucial to preserve functionality and efficacy at the site of action.

Product Development – Extracts

MartinBauer

Manager Sales – Animal Nutrition Industry

MartinBauer

And Celina Jordan, Product Development – Extracts (Internship) at MartinBauer

The livestock sector is under increasing pressure to balance performance, profitability, and sustainability. While feed efficiency and productivity remain central, there is growing focus on improving product quality (e.g. nutrient density, sensory characteristics), animal welfare, and reducing reliance on antibiotics. These shifts reflect evolving consumer expectations and tightening global regulations.

In this context, botanicals – including herbs, spices, and plant extracts – have attracted renewed attention. Their bioactive constituents such as essential oils, flavonoids, phenolic acids, tannins, and saponins are known for a broad spectrum of functional properties. These include antioxidative, antimicrobial, immunomodulatory, or digestion-enhancing effects, offering potential to improve animal resilience and reduce dependency on synthetic additives or therapeutics.

However, realizing this potential requires more than just selecting the right plant. The stability of phytogenic ingredients during feed processing, storage, and digestion is a critical factor that determines their effectiveness. Many botanical substances are inherently sensitive to environmental factors such as temperature, light, oxygen, and pH changes. If these actives degrade before reaching their site of action in the animal, their functional value is lost.

STABILITY: A CRITICAL CHALLENGE FOR BOTANICAL FUNCTIONALITY

During feed manufacturing, steps like pelleting, extrusion, or drying expose ingredients to thermal and mechanical stress. Additionally, long-term storage and exposure to oxygen can cause oxidative degradation of sensitive actives. These processes can lead to loss of structural integrity, reduced bioactivity, and ultimately, diminished performance outcomes.

Close the Gap Between Botanical Potential and Performance

This degradation not only compromises the intended functional effect (e.g. supporting gut integrity or immune response) but can also result in inconsistent product performance and economic loss for feed manufacturers and livestock producers. Ensuring stability through production and delivery is therefore essential to harness the full benefits of botanicals.

At MartinBauer Animal Nutrition, we aim to close this gap between potential and performance. By investigating the resilience of selected botanical extracts under real-world feed processing and storage conditions, we provide insight into how to preserve bioactivity and ensure reliable, science-based application of botanicals in animal nutrition.

![]() SIMULATING REAL-WORLD CONDITIONS

SIMULATING REAL-WORLD CONDITIONS

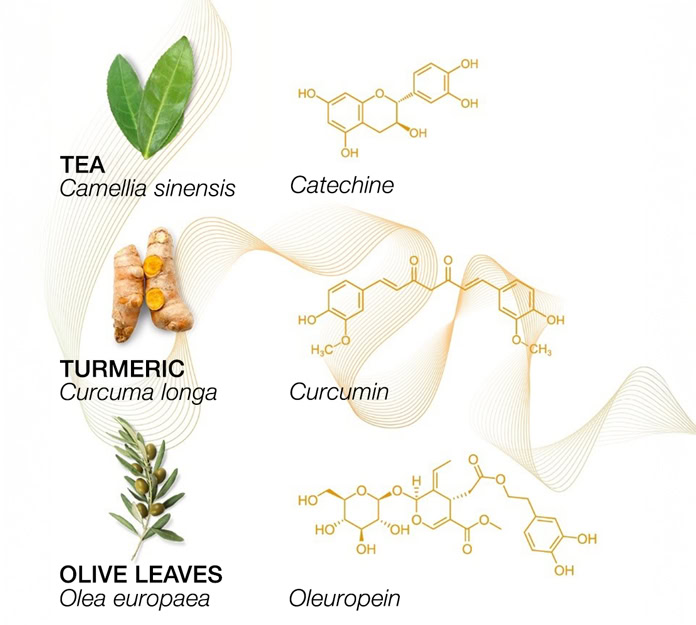

In an in-house study, three botanicals shown in Figure 1 were evaluated for the stability of their key bioactives under different stress conditions. A blend of their extracts (1% turmeric, 1.5% green tea, 1.5% olive leaves) was incorporated into a simplified feed matrix composed of pea protein (14%), waxy corn starch (16.5%), fibers (1.5%), rapeseed oil (7.5%), and water (56.5%). The bioactive markers in Table 1 were selected to investigate degradation.

EXPERIMENTAL SETUPS

To simulate practical challenges in feed manufacturing and storage, the feed matrix was tested under three conditions:

1. Multifactorial stress test

Samples were subjected to combinations of temperature (room temperature, pasteurization 100 °C for 2 minutes, sterilization 121 °C for 3 minutes), pH levels (5 and 7), and light exposure over 48 hours to simulate 1 year shelf-life conditions.

2. Extrusion test

The matrix was processed at 110 °C and 5 bar to assess thermal stability under pressure with a high-shear double twin extruder in pilot scale at 3 kg/h product output.

3. Oxidative stability test

The feed was stored in a sealed chamber with pure oxygen at 700 kPa and 100 °C. Induction time (defined as 10% pressure drop) was measured to assess antioxidative potential.

Degradation of phytogenic compounds was quantified using HPLC-UV/Vis, allowing precise monitoring of compound integrity across conditions.

Multifactorial Stress – Stability in Application is Key

Key findings (Figure 2) include:

• Temperature was the dominant factor influencing degradation. All active substances declined significantly with rising heat. EGCG showed to be sensitive towards temperature catalyzed oxidation, with concentrations dropping by ~50% at pH 7.

• pH had a complex effect. At room temperature, most compounds were more stable at pH 7 – except EGCG. Under thermal stress, EGCG, and oleuropein showed higher stability at pH 5, whereas curcumin remained consistently more stable at pH 7.

• Light exposure showed negligible impact under the conditions tested.

![]() EXTRUSION PROCESSING – HEAT SENSITIVITY COUNTS

EXTRUSION PROCESSING – HEAT SENSITIVITY COUNTS

Key findings (Table 2) include:

• EGCG again proved most heat-sensitive aligning with results from the multifactorial test.

• Oleuropein and curcumin demonstrated exceptional thermal resilience, with minimal degradation.

• Interestingly, curcumin showed greater stability under extrusion than in static thermal stress. This may be due to matrix effects or protective interactions with other actives acting as sacrificial antioxidants during rapid, high-pressure processing.

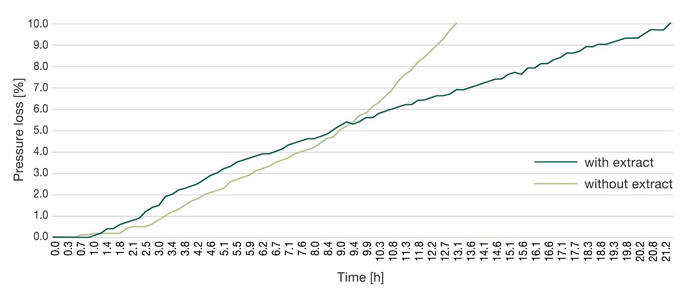

OXIDATIVE STABILITY – STRONG ANTIOXIDATIVE SYNERGIES

In the oxidative stress setup, induction time was used as a proxy for antioxidant capacity. As shown in Figure 3, the blend of the botanical extracts doubled the induction time compared to the control matrix without extracts. This result highlights the strong antioxidative synergy between botanicals, suggesting improved shelf-life potential for feed formulations containing such blends.

CONCLUSION: BOTANICAL KNOW-HOW FROM SOURCE TO STABILITY

The use of botanical ingredients in animal nutrition holds great promise – but realizing this potential requires more than just selecting a plant with functional benefits. It demands a deep understanding of the chemical behavior of active substances under the practical conditions of feed processing, storage, and digestion.

Our findings confirm that thermal and oxidative degradation are key barriers to efficacy, particularly for sensitive compounds such as EGCG. Conversely, compounds like oleuropein and curcumin show considerable resilience, especially under extrusion. The results also suggest that strategic combinations of actives can enhance overall matrix stability, both through synergistic effects and oxidative buffering.

At MartinBauer Animal Nutrition, we apply our expertise in botanical sourcing, extraction, and standardization to help the feed industry go beyond trial-and-error. By linking phytochemical science with practical formulation needs, we support our partners in creating plant-based solutions that are not only functional – but stable, scalable, and reliable from seed to feed.

About Dr. Lisa-Marie Sandberg

As Manager of Sales Animal Nutrition at MartinBauer, Dr. Lisa-Marie Sandberg applies her nutritional expertise in animals to bring the beneficial properties of botanicals into the feed industry. With a Ph.D. in Animal Breeding and Husbandry from Kiel University and earlier degrees in Animal Science and Agroecology from University of Rostock, she combines a strong academic foundation with seven years of industry expertise. Dr. Lisa-Marie Sandberg is passionate about developing plant-based solutions that enhance animal performance, by translating latest research into practical feed solutions and market strategies.About Tobias Härtel

As a Product Developer at MartinBauer, Tobias Härtl combines his phytochemical knowledge from his master’s degree in chemistry at the ‘Friedrich-Alexander-University Erlangen’ with his experiences from his own academic research in the field of sensory sciences at the ‘Chair of Aroma and Smell Research’. Tobias Härtl is passionate about creating plant-based solutions that combine the latest scientific findings with deeply rooted traditional knowledge – always with the aim of highest functionality and performance in animal feed, while precisely meeting application requirements.