Feed biosecurity involves implementing comprehensive procedures to prevent the introduction and spread of disease-causing pathogens throughout animal production systems. Given feed’s widespread distribution and direct access to food-producing animals, it has become a critical focal point for biosecurity innovation.

Technical Director

Anitox

Heightened awareness of bacterial and viral pathogens, resulting from high-profile outbreaks, have highlighted the critical need for comprehensive biosecurity. With recent and ongoing research demonstrating that feed can serve as a vector for pathogen transmission within the food animal production chain, it remains an important point for effective intervention.

The challenge extends beyond initial contamination. Even after pelleting, bacterial populations rapidly rebound, creating re-contamination before feed ever leaves the mill. This biological reality demands sanitizers with genuine residual control—not just kill-and-fade solutions.

Feed biosecurity involves implementing comprehensive procedures to prevent the introduction and spread of disease-causing pathogens throughout animal production systems. Given feed’s widespread distribution and direct access to food-producing animals, it has become a critical focal point for biosecurity innovation.

![]() OUTBREAKS RESHAPE BIOSECURITY APPROACHES

OUTBREAKS RESHAPE BIOSECURITY APPROACHES

The Porcine Epidemic Diarrhea Virus (PEDV) outbreak in 2014 affected 23 states and caused devastating mortality rates among piglets, and in 2018, African Swine Fever (ASF) led to the culling of millions of pigs in China and severely disrupted global pork supplies. In the poultry sector, we continue to see Avian Metapneumovirus and Highly Pathogenic Avian Influenza (HPAI) pose serious challenges.

Each outbreak leaves its mark on producer approaches to biosecurity across the industry, with practices such as feed sanitation, which were once limited to genetic companies, being widely adopted throughout the production chain. While viral outbreaks often make headlines, bacterial pathogens remain a persistent concern in animal feed.

For years, we have understood the ingress of bacterial pathogens such as Salmonella, E. coli and Clostridia into live production. Feed ingredients, equipment and vehicles can harbor pathogens that may contaminate finished feeds. Once contaminated, these feeds can spread widely throughout multiple barns or housing facilities across an operation, potentially affecting many animals.

Salmonella in feed has been extensively studied over the past 30 years. According to Davies et al. (2004), contaminated feed is a recognized source of Salmonella infection in pork production. Foley et al. (2008) identified the main serovars affecting swine and poultry production systems, including S. typhimurium, S. enteritidis, S. heidelberg, S. montevideo, S. saintpaul, and S. I 4,[5],12:i:-.

What makes bacterial pathogens particularly challenging is their ability to adapt and mutate to survive in different conditions. Without thoroughly cleaning on a frequent basis, they can persist in feed manufacturing facilities and transportation environments, requiring comprehensive security measures throughout the supply chain. More recent research shows that viruses can survive in animal feed and cause infections in challenge studies, though our understanding of this process is not as extensive as our knowledge of bacterial transmission via feed. This highlights why strong biosecurity measures are crucial for disease prevention.

THE CRITICAL IMPORTANCE OF FEED SANITATION

Feed sanitation has emerged as a cornerstone of comprehensive biosecurity programs across the animal production industry. Effective feed sanitation is no longer optional—it’s a fundamental requirement for protecting animal health, ensuring food safety, and maintaining production efficiency.

Feed sanitation encompasses multiple intervention strategies designed to eliminate or significantly reduce pathogen loads in animal feed before consumption. These strategies are particularly important given the increasing complexity of global feed supply chains and the recognition that traditional processing methods such as pelleting would not provide prolonged pathogen control.

What many producers don’t realize is that even with thermal processing like pelleting, bacterial recontamination can occur right after the pellet leaves the pellet mill during cooling and storage phases. A comprehensive sanitation approach needs to address the entire production cycle, not just individual processing steps.

Key components of effective feed sanitation programs include:

• Preprocessing treatments for incoming raw materials to reduce initial pathogen loads

• Chemical interventions during feed manufacturing that provide residual protection against recontamination

• Environmental sanitation of production facilities, storage areas, and transportation equipment

• Regular monitoring and verification to ensure sanitation protocols maintain effectiveness over time

Research has demonstrated that properly implemented feed sanitation programs can reduce microbial loads in finished feed products, providing substantial protection against common bacterial threats, such as Salmonella. Beyond pathogen control, sanitation measures often deliver secondary benefits, including enhancements in feed quality through reduced microbial loads and animal performance.

The health and performance of poultry depend critically on gut health and microbiome balance, which can be disrupted by variable microbial loads in feed. When high levels of pathogens are present, the bird’s system diverts energy to defense mechanisms, such as increased mucus production by goblet cells, rather than growth.

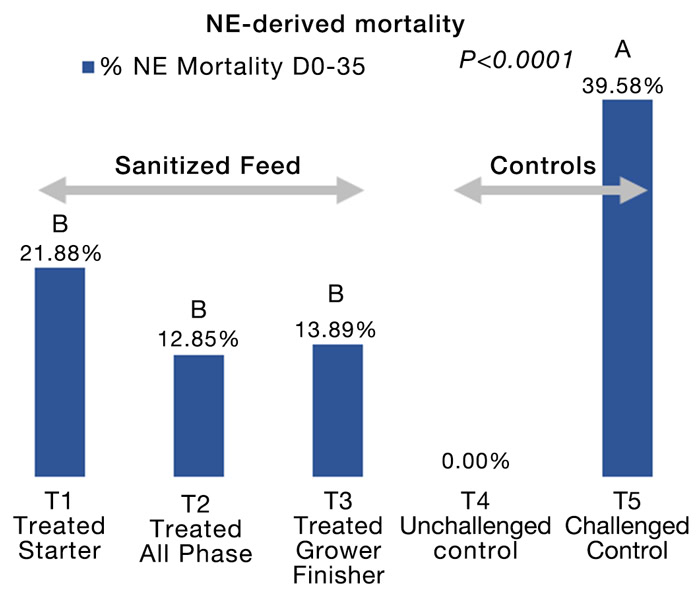

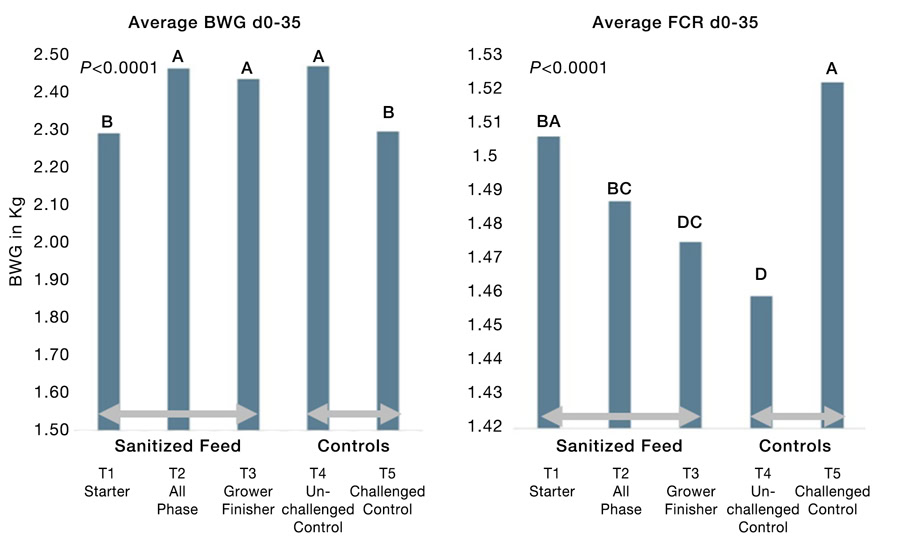

For example, research by Dr. Dan Moore at Colorado Quality Research demonstrated that sanitized feed reduces mortality by at least 50% (Figure 1) and lesion severity (Table 1) in broilers challenged with clinical necrotic enteritis (NE). While birds receiving sanitized starter feed (T1) avoided high mortality, they still showed reduced performance in weight gain and FCR. However, birds receiving sanitized feed during the actual challenged period- either grower finisher treated (T3) or all phase treated (T2) – performed similarly to non-challenged control (T4) in weight gain, showing that timing of sanitized feed application is critical for maintaining performance during a disease challenged scenario.

![]() While the body of research demonstrating that decreasing microbial loads in feed supports better poultry health and performance continues to grow, researchers note that more work is required to fully understand the mechanisms connecting feed sanitation to microbiome development and intestinal health.

While the body of research demonstrating that decreasing microbial loads in feed supports better poultry health and performance continues to grow, researchers note that more work is required to fully understand the mechanisms connecting feed sanitation to microbiome development and intestinal health.

When evaluating the economic aspects of feed sanitation, producers with budget constraints should strategically target treatment during the most critical production phases when disease risk is highest, when comprehensive all phase treatment is challenging. This targeted approach balances intervention costs against the potential financial impacts of disease outbreaks, performance losses, and market disruptions that contaminated feed can trigger.

DETECTION CHALLENGES AND CONTROL STRATEGIES

One of the biggest challenges in combating feed-source pathogens is understanding their load and prevalence in feed. According to Alali (2012), uneven distribution and damage to bacteria in feed can lead to false negative results during microbial testing. Additionally, it has been noted that the complexity of modern livestock production systems further complicates data collection and surveillance efforts (Padungtod et al., 2008).

Feed sampling has traditionally been conducted to ensure feed uniformity, monitor quality, and evaluate nutrient content and digestibility. However, sampling plays an equally crucial role in determining feed microbial risk.

Microbial loads aren’t distributed evenly throughout feed. Proper sampling is essential to accurately estimate fungal, bacterial, and viral contamination.

Strategic sampling provides valuable information in three key areas: feed quality assessment (nutrient content, moisture, microbial loads), batch uniformity verification, and production process evaluation for pathogen control.

Research by Gosling et al. (2022) exemplifies effective process evaluation, finding Salmonella in 20 of 22 surveyed commercial feed mills, with 75% showing less than 5% positive samples. This study demonstrated how strategic sampling can identify resident bacteria in mill environments, with concerning evidence that common feed mill Salmonella serovars matched those in broiler flocks.

During the feed production process, microbial loads typically decrease after pelleting and conditioning. However, mills with legacy bacteria problems show distinctive recontamination patterns post-processing that strategic sampling can detect before downstream issues emerge. Truly effective pathogen reduction requires improved monitoring programs, sensitive detection methods and intervention strategies such as feed sanitation which provides long-term protection against recontamination.

THE EVOLUTION OF INDUSTRY RESPONSE

The understanding of feed and ingredients as potential sources or fomites for pathogens has evolved significantly. What we’ve seen is a fundamental shift in producer’s attitudes toward biosecurity. With limited treatment options available for many diseases, prevention through enhanced biosecurity measures has become the industry’s most effective approach.

As industry continues to adapt to these challenges, companies such as Anitox are leading the way in developing comprehensive feed biosecurity solutions that address both current and emerging threats to animal health and food safety.

References

1. Alali, W.Q. (2012). [Details of study on microbial testing in feed]

2. Crump, J.A., et al. (2002). Bacterial contamination of animal feed and its relationship to human foodborne illness.

3. Davies, R.H., et al. (2004). [Study on Salmonella infection in pork production]

4. Foley, S.L., et al. (2008). [Research on Salmonella serovars in swine and poultry production]

5. Hinton, M., et al. (1993). [Study on bacterial pathogens in animal feed]

6. Padungtod, P., et al. (2008). [Research from Thailand on bacterial contaminants in animal feed]

About Dr. Yun-Mei Amy Lin

Receiving her Ph.D. in Poultry Science from North Carolina State University, Dr. Yun-mei Amy Lin has over five years of industry experience. Her extensive academic background and professional experience have equipped her with a deep understanding of the complexities of animal and poultry science. Dr. Lin is deeply passionate about food sustainability and dedicated to ensuring the highest standards in animal health and safety.